Máy đo độ đục trong dòng 118442 Sigrist

Xuất sứ: 100% Germany Origin

Nhà cung cấp: STC Vietnam

Sigrist Vietnam,Máy đo độ đục trong dòng 118442 Sigrist

Turbidity measurement using scattered light

The TurBiScat determines turbidity with optimum color compensation using 650 nm scattered light measurement and is thus MEBAK/EBC compliant. Adapted to individual requirements and applications, the instrument covers a measuring range of 0 - 1000 EBC and can be variably configured for single or dual angle measurement. However, the significance of the turbidity measurement can be enormously increased by the dual angle measurement. Thus, in addition to conventional filtration monitoring at 90°, the additional 25° measuring angle allows the following two quality checks to be carried out:

-

checking the filter construction

-

early warning of a filter break

Integrated color measurement

Optionally, the TurBiScat can be equipped with an integrated MEBAK/EBC/ASBC compliant color measurement (430 nm) up to 50 EBC/SRM 25.4. This flexible 2 in 1 integration option results in cost advantages in the acquisition on the one hand as well as savings in process connections on the other hand. A further advantage are the numerous possible applications in the brewhouse, filter cellar and pressure tank.

Low maintenance, sealless and sustainable design

The sensor head is made of corrosion resistant Hastelloy®, the window of the measuring cell consists of high-quality sapphire glass. Its integrated LED lamp requires little power consumption and has a service life of at least 10 years; replacement during this period is therefore completely unnecessary. The compact, sealless design can be easily and quickly installed in a Varinline® or compatible housing, allowing it to be used in virtually any process application.

Fig. 1: Features TurBiScat

Reliable and fast quality assurance

The TurbiScat has an automatic cyclical self-check which checks all functions of the instrument on a daily basis and issues a warning in case of a fault. In addition to the optical functions, all other parameters of the instrument are permanently monitored by the instrument and shown as plain text messages on the display.

Since the TurbiScat is a testing instrument, SIGRIST supplies an extra certified testing specimen with which the certification obligation can be fulfilled at any time and without external service personnel. The test is carried out using a life-long stable solid reference. Thus, neither tools nor toxic chemicals such as formazine are necessary, which is in turn beneficial to health and the environment.

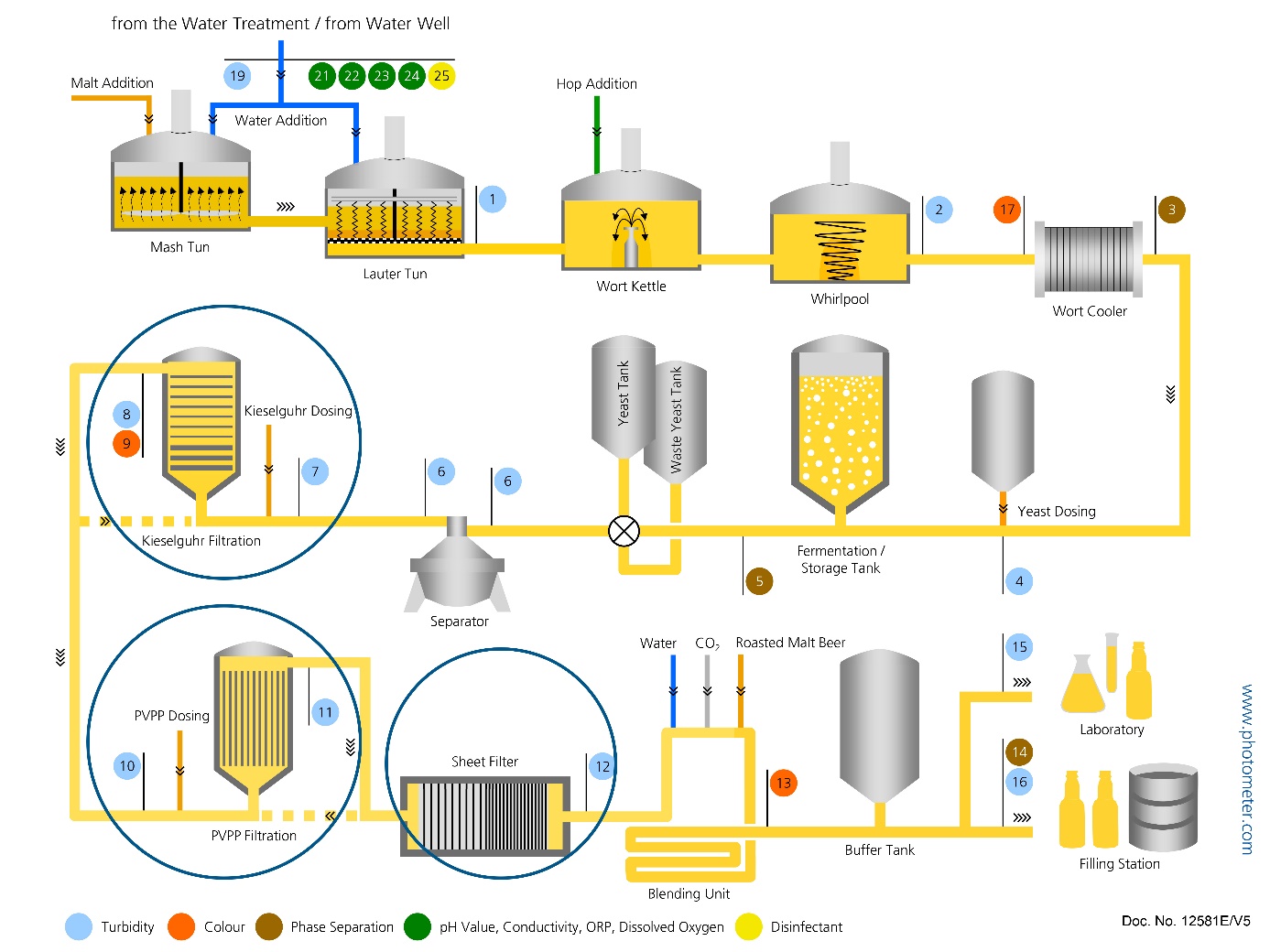

SIGRIST TurBiScat monitoring and controlling filtration

Classic beer filtration consists of at least one kieselguhr filter, usually followed by a fine filter and, in larger breweries, a PVPP filter for stabilization. For measuring turbidity, the outlet of the kieselguhr filter is the most important point of installation. The turbid, unfiltered beer is freed from a large number of clouding substances in the filter with the aid of the highly porous kieselguhr. These include particulate substances such as yeast as well as dissolved (colloidal) clouding agents such as proteins and glucans.

Fig. 2: Measuring points of the SIGRIST TurBiScat for filtration monitoring and controlling

Turbidity measurement has to permanently detect even small changes in the turbidity of the filtrate in order to provide the operating personnel with information on how to control the filter. If the 90° proportion of turbidity increases then, for example, the kieselguhr mixture of coarse and fine matter has to be changed. If the 25° turbidity value increases relatively suddenly, this can mean a so-called filter break. In this case, the filter automatically switches to a closed circuit with continuing dosage of kieselguhr until the damage in the filter cake has closed. The measured values of the turbidity measurement are thus the most important indicators for the quantity and mixture of the filter aids. In general, it can be said that the 90° value covers colloidal turbidity of less than 1μm. The consumer sees this turbidity as a light veil (opalescence) in the beer which in turn causes complaints. The 25° value on the other hand is more sensitive to larger particles.

For more than 75 years and with continuous further development, the 25° forward scattered light angle has proven to be the optimal configuration to prevent disturbing reflections caused by measuring angles that are too small. This makes the 25° measurement angle best suited for particle detection. The world's leading breweries have adopted the proven combination of 90/25° angle measurement. The TurBiScat 90/25° naturally provides these measured values color-compensated.

We would be pleased to show you the possible applications on site or assist you with your projects. Our large network of sales and service partners provides competent advice worldwide and supports you locally in the practical use and service of all SIGRIST products and systems.

100% Switzerland Origin |

Sigrist Vietnam |

P/N: 118442

|

100% Switzerland Origin |

Sigrist Vietnam |

P/N: 121121

|

=====================================================

Click xem thêm ứng dụng sản phẩm khác

Đại lý phân phối chính hãng tại Vietnam

Báo giá ngay – Hàng chính hãng – Bảo hành 12 tháng – Tư vấn hỗ trợ kỹ thuật 24/7